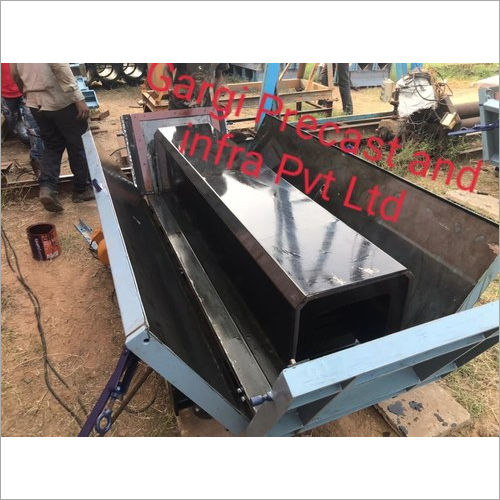

U Shape Drain Mould

500000 INR/Piece

Product Details:

- Cavity Single or Double

- Molding Material Concrete / Precast Mix

- Life Span 58 years

- Mold Base High-grade Steel

- Shaping Mode U Shape

- Material Alloy Steel / Customized

- Tolerance 0.05 mm

- Click to View more

X

U Shape Drain Mould Price And Quantity

- 1 Piece

- 500000 INR/Piece

- Customized from 100 mm to 300 mm

- Construction, Roadways, Drainage Systems

- Natural Steel / Customized

- 150 mm to 450 mm width (Custom sizes available)

- Hydraulic/Manual press machine

- Easy cleaning and low maintenance

- Up to 180°C

- Forming U-shaped drain channels

- Smooth, Anti-corrosive

- Fixed or Detachable Core

U Shape Drain Mould Product Specifications

- U Shape

- Single or Double

- 80,000120,000 shots

- Concrete / Precast Mix

- 58 years

- Alloy Steel / Customized

- 0.05 mm

- High-grade Steel

- 120250 kg

- Customized from 100 mm to 300 mm

- Construction, Roadways, Drainage Systems

- Natural Steel / Customized

- 150 mm to 450 mm width (Custom sizes available)

- Hydraulic/Manual press machine

- Easy cleaning and low maintenance

- Up to 180°C

- Forming U-shaped drain channels

- Smooth, Anti-corrosive

- Fixed or Detachable Core

U Shape Drain Mould Trade Information

- 60120 seconds

- 3 Piece Per Month

- 20 Days

Product Description

We are one of the well-distinguished companies in the market that are into providing U Shape Drain Mould. It is going directly into the drainage system. Apart from this, provided mould is made with a stainless steel material to make it sturdier. This mould is used on the side of the roads to trap the rain water from getting on the road. U Shape Drain Mould is designed by our hardworking crew members to give the best possible material in the market.

Precision Engineering for Construction Needs

Our U Shape Drain Mould allows you to form durable, smooth-surfaced U-shaped drainage channels with high dimensional accuracy. With customizable width and depth, this mould meets various site-specific requirements, offering reliability for heavy usage in construction and road infrastructure.

Long-Lasting Performance & Easy Maintenance

Made from premium alloy steel, the mould boasts an impressive shot life and minimal maintenance needs. Its anti-corrosive finish not only extends operational lifespan but also ensures seamless cleaning and upkeep, making it a dependable investment for large-scale projects.

Versatile Application & Compatibility

Compatible with hydraulic and manual press machines, the mould adapts smoothly to different manufacturing setups. Whether producing single or double cavity drains with concrete or precast mixes, it delivers consistent performance and straightforward processing for contractors and builders.

FAQ's of U Shape Drain Mould:

Q: How can the U Shape Drain Mould be customized for specific project requirements?

A: The mould offers flexibility in width (150 mm to 450 mm) and drain depth (100 mm to 300 mm), and you can request custom sizes to suit unique project needs. Customization extends to core type (fixed or detachable) and color to match application demands.Q: What benefits does using this mould provide in drainage system construction?

A: The mould yields robust U-shaped drain channels with smooth, anti-corrosive surfaces, ensuring durability and efficient water flow. Its easy-to-clean design and low maintenance reduce long-term operational costs while enhancing project reliability.Q: Where is the U Shape Drain Mould commonly utilized?

A: It is widely used in construction sites, public roadways, and various drainage system installations, both in urban and rural infrastructure development across India and for export to worldwide markets.Q: What is the recommended process for operating the mould?

A: Operate the mould using either hydraulic or manual press machines, filling it with concrete or precast mix. The fixed or detachable core design facilitates straightforward shaping and demolding of U-shaped channels.Q: When should maintenance be performed for optimal mould life?

A: Regular cleaning after each production cycle and routine inspection for wear are recommended. With proper care, the mould achieves a life span of 5 to 8 years and supports up to 120,000 production shots.Q: How does the mould's temperature resistance benefit construction applications?

A: Withstanding temperatures up to 180C, the mould supports high-temperature curing processes, ensuring uniform channel strength and reliability under demanding construction conditions.Q: What materials are compatible with this U Shape Drain Mould?

A: It is designed for use with concrete and precast mix materials, supported by a high-grade steel base and durable alloy steel body. Mould materials and colors can be customized as needed.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS